Over the last 150 years, the railroad industry has changed in countless ways. One of the most significant ways is the number of workers who work in the industry. According to an article in the Washington Post, there were over 2 million railroad workers in the early 1900s; today the number is approximately 134,000. Given the huge drop in the number of railroad employees, one would expect that the rates of railroad worker death and injury would be nonexistent. Unfortunately, railroad injury rates remain high, especially in switching operations which leads to an obvious question: Why do railroad workers continue to get injured or die at alarmingly high rates?

Other blogs have looked at the obvious reasons, including Precision Scheduled Railroading, the willingness of railroad boards and CEOs to bend to the will of Wall Street investors in the push for profits over safety, and the fact that certain activities will always be inherently dangerous. One of the most dangerous activities is the switching of rail cars in yards.

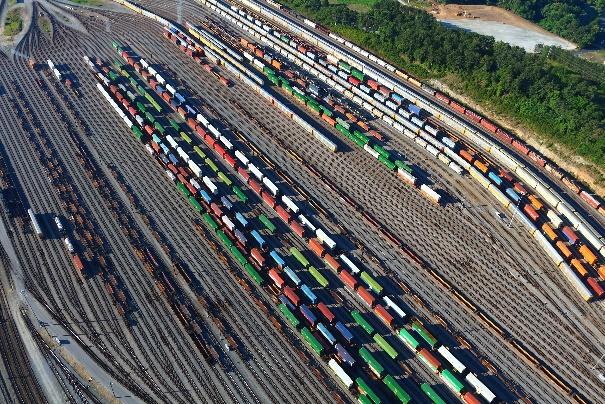

Switching is the process during which railcars are placed in different tracks within yards so they can be transported to their final destinations. Switching can be done in two different ways: (1) in hump yards where the cars roll down a small decline (“hump”) into the assigned tracks or (2) by “flat switching” where cars are pushed or shoved into the correct tracks. Regardless of the way the switching is done, there are risks involved because railroad workers are working in busy rail yards while rail cars are being moved all around them. Common causes of railroad worker switching injuries include:

- Workers being struck by moving rail cars in yards, especially during non-daylight hours

- Workers being struck by railcars that have been switched to the wrong track

- Locomotives (with engineers or conductors inside) being struck by rail cars that have been switched into the wrong track

- Conductors, Brakemen, and Switchmen being hurt by defective switches that fail to operate properly

- Railroad yard crews injuring their backs, necks, and shoulders while tying down or releasing defective handbrakes on rail cars

- Railroad yard crews being injured while pulling defective cut levers or aligning drawbars that don’t operate as they are supposed to

- Rail yard crews being injured due to poor walking conditions on ballast while switching rail cars

Railroad workers who are injured while switching rail cars are protected by the Federal Employer’s Liability Act (FELA) and are able to claim benefits when the railroad fails to provide a safe place to work. Railroad worker switching injuries that are caused by defective equipment also have the protection of another important safety law, the Federal Safety Appliance Act (FSAA) which imposes absolute liability on the railroads if safety appliances (handbrakes, cut levers, drawbars, ladders, or sill steps) are defective or don’t operate as intended. Absolute liability means that the railroad is 100% liable and that even if the railroad worker is partially at fault they can get 100% of the compensation that is owed to them for lost wages, medical bills, and pain and suffering.

An experienced FELA railroad injury lawyer can guide you through the steps to get compensation for your injuries. Call the lawyers at Doran and Murphy to learn about your rights and what you can do to protect your family!